Commerical office – Technical office

- Personalised and quick quotes

- Listening to customer’s needs

- Advice and help given with design

- Project studies

- More than 25 years of experience and knowledge

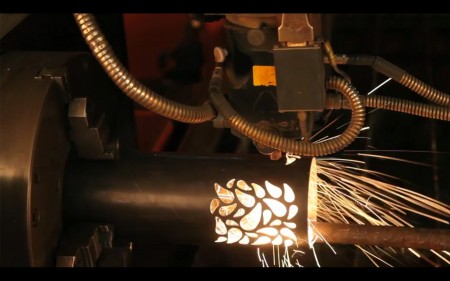

- Total control of the production process

- Study of 2D and 3D drawings

- Engineering

- Design assistance

- Feasibility study and technical advice

- Prototyping, taking measurements, manufacturing processes are apadted

- PEPS updated performance software, TruTops, Solidworks, Solid Edge

- Guaranteed, files and data are archieved for 10 years